Help you solve

-

Large mold small weight product molding difficult

-

Halogen free and high glass fiber plastic screw, barrel wear-resistant, non-corrosion-resistant

-

Screw tip of poor wear resistance,and the screw tip is liable to fracture

-

PC white plus brightener computer shell molding process yellow, black, black spots and other issues

R&D

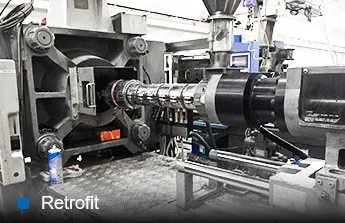

Kotler has a proven solution to the problems that arise in the molding of small molds. The program has been applied to many well-known brand Injection molding machine such as Haitian, Toshiba, Sumitomo, Allianzhan, and Zhenxiong involving in power tools, IT products, auto parts and other industries. Successfully solved the high rate of molding defects, low efficiency. And for customers to save the cost of purchase.

Technology R&D team has decades of industry experience, has in-depth study on the characteristics of various plastics and molding process, mold, well-known characteristics of famous Injection molding machine. Provide customers professional solutions and the most suitable screw, barrel selection meet their production requirements。

Our technical service

-

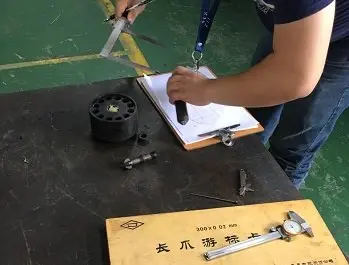

Screw barrel and other components of the site measurement, mapping

-

Screw and barrel reform program development

-

Forming easy-shaped analysis and rationalization proposals

Site service

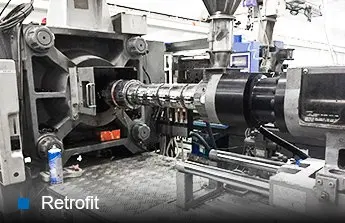

Kortler has an experienced service team, after-sales department 7 * 24 to provide after-sales customer service problems, technical advice and maintenance tracking

1. Technical support according to different plastic raw material and molding process to choose a reasonable screw structure and material

2. The machine, improve the molding process, to solve the poor product

3. Field measurement, testing of screw and brrel, give written report on the problems found, and give reasonable suggestions

-

Customer service disassembly

-

Site Service

-

Site mapping

You are here:

You are here: